Excimer-UV-Lacke

Unsere Excimer-Lacke bilden absolut kratzfeste Oberflächen zum Schutz Ihres Produktes. Durch die chemische Einstellung der Oberflächenfaltung können verschiedene Mattierungsstufen von Glanzgrad 1 bis ca. 15 eingestellt werden.

Unsere Lacksysteme können theoretisch auch auf Basis recycelter oder nachwachsender Rohstoffe entwickelt werden, nähere Infos finden Sie hier.

Folgende Funktionen bzw. Modifikationen unserer individuell auf Ihre Bedürfnisse hin entwickelten Excimerbeschichtungssysteme sind realisierbar:

Folgende Funktionen bzw. Modifikationen unserer Beschichtungssysteme sind je nach Einsatzzweck einstellbar:

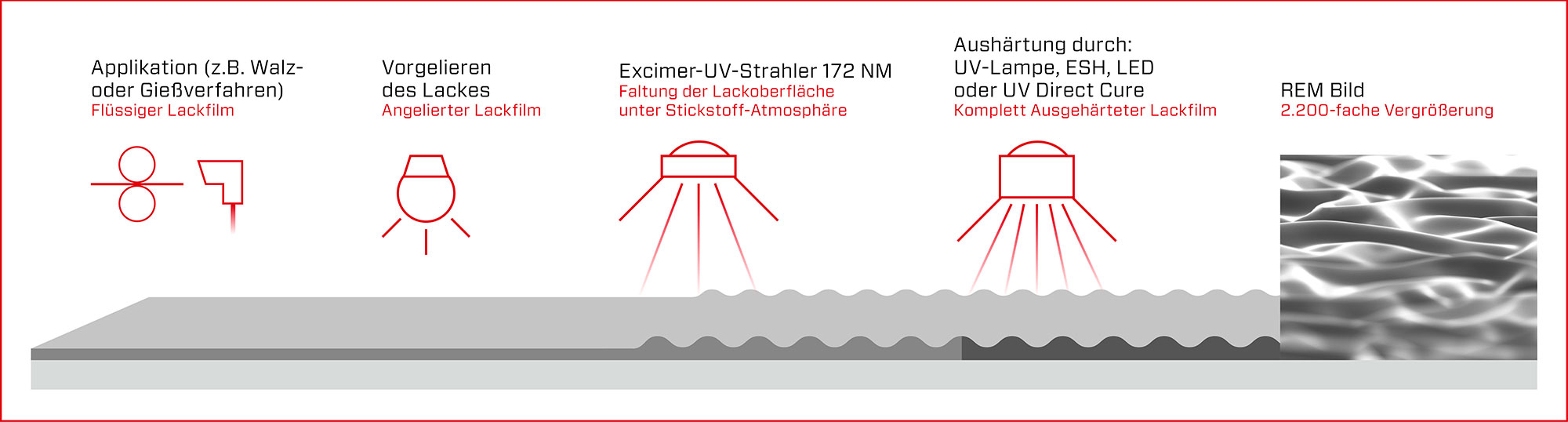

Das Prinzip der Ecximer Lackierung führt zu tiefmatten und hochresistenten Oberflächen: Zu Beginn des Prozesses wird der Lack auf das Substrat im Walz- oder Gießverfahren aufgebracht. Das Angelieren mittels UV-, PAC- oder LED-Technologie beeinflusst außerdem die Haptik des Lackes nach der Aushärtung. Zusätzliche Eigenschaften wie eine Soft-Touch Oberfläche oder ein Anti-Fingerprint-Effekt lassen sich so erzielen.

Bei einer Wellenlänge von 172 nm verfügen Excimer-Lampen erfahrungsgemäß über eine sehr energiereiche Emission, die im obersten Teil einer Schicht aus UV-härtbarem Lack einen Polymerisationsprozess startet. Die Eindringtiefe der Excimer-UV-Emission ist jedoch vergleichsweise niedrig, sodass dieser Prozess nur einen dünnen Film auf dem flüssigen Lack hinterlässt, ohne tiefer liegende Lackschichten auszuhärten. Diese Filmbildung führt zu einer Schrumpfung des Lackes, und so entwickelt der oberflächennahe Lackfilm sogenannte Mikro-Faltungen. Diese lassen sich in der abschließenden Endhärtung durch herkömmliche UV-, LED- oder ESH-Technologie mit dem gesamten Lack in voller Schichtiefe aushärten. Das Ergebnis ist eine tiefmatte, mechanisch und chemisch hochresistente Oberfläche.

Tiefmatte Lacke sind derzeit vor allem in der Möbelindustrie sehr stark nachgefragt. Wir entwickeln mit unseren Excimer-Lacksystemen die Grundlagen für homogene Mikro-Faltungen an der Lackoberfläche, die sich auch unter dem Rasterelektronenmikroskop hervorragend darstellen lassen.